Industrial insect farming solutions

What do you expect from an insect monitoring solution?

- React more quickly

- Be more accurate

- Monitor your production more efficiently

- Reduce losses

- Increase your production rates

- Accelerate the development of your company

- Optimize quality control

👉 Our solution dedicated to insects will make you accelerate your production control and quality control in a spectacular way!

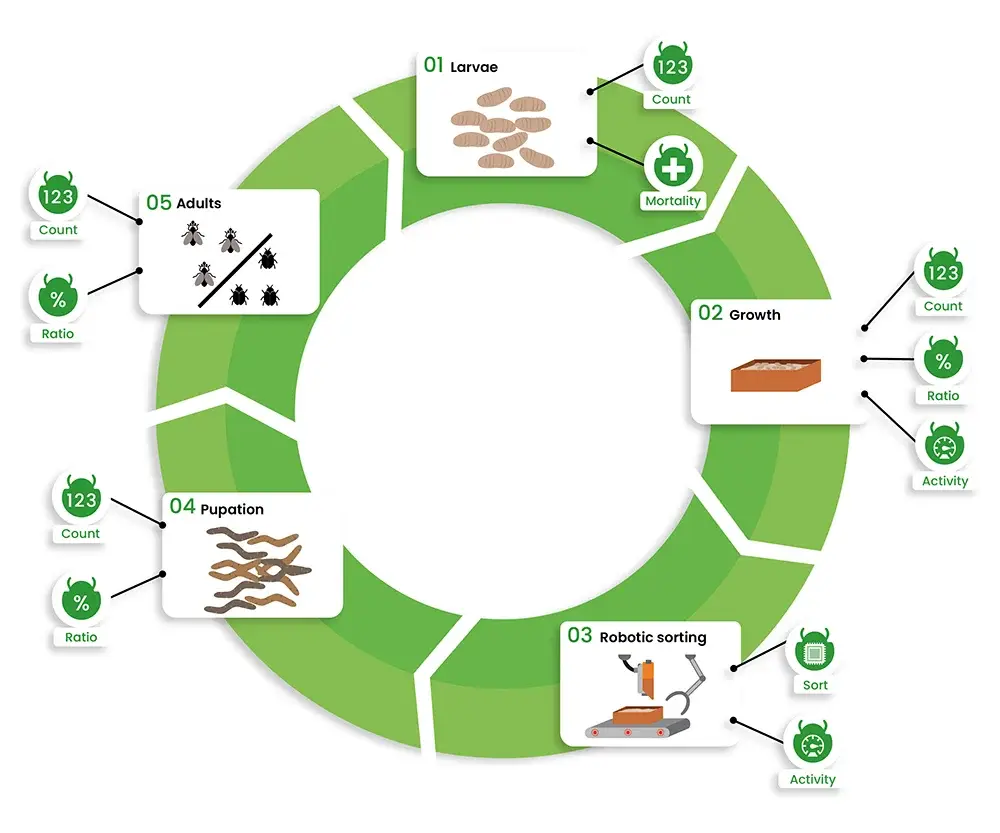

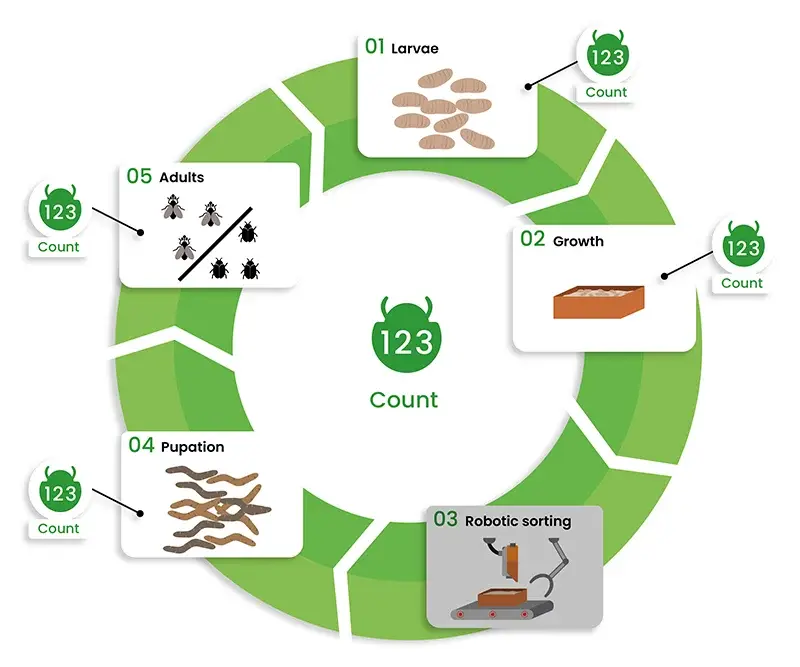

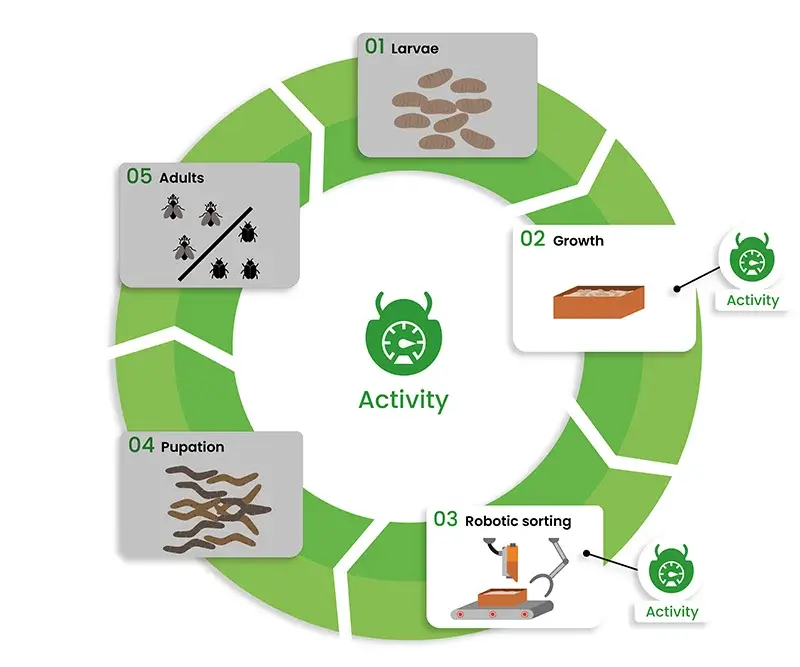

#2 Save time and precision at every stage of production

The analysis points, which are present at different units in a plant or at different plants, all operate with the same accuracy. They allow performance to be analysed at different scales.

Our solution can be duplicated at different stages of production

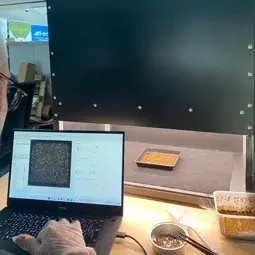

#3 Our insect counting solution in action

Black soldier fly (Hermetia illucens) larvae are placed in a sample tank commonly used in industrial insect farming.

In this case, the sensor is placed on top of the sample tray to perform acquisitions. The samples are spread out in the tray to minimise the coverage of the larvae by their substrate.

Once sent to our analysis platform (www.dilepix.io), it only takes a few seconds for our counting solution to estimate the number of larvae present in the tank.

Learn more about our counting solution

#4 Our innovative solutions to save you time and precision

Present on different stations of a plant or on different plants, the analysis points all work with the same precision and allow to analyze the performances at different scales.

Automatic BSF larvae counting in seconds

Save time and accuracy with Prolarvae, our automatic larvae counting solution, which allows you to perform stationary larvae counting operations in seconds.

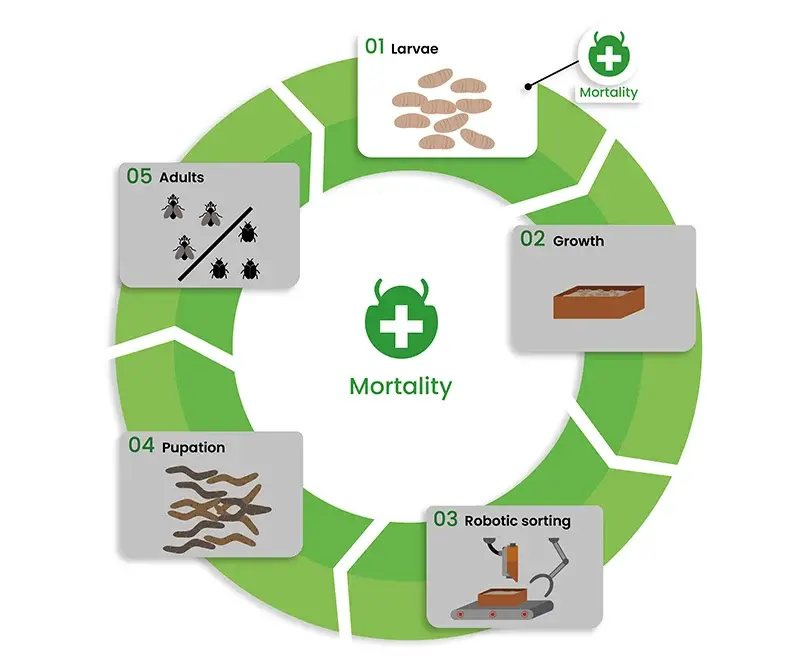

Automatically estimate the larvae mortality rate even in cluster form

Instantly estimate the quality of your production with the DPX-Mortality software solution, which allows you to evaluate the mortality rate of a larval sample.

Page in progress

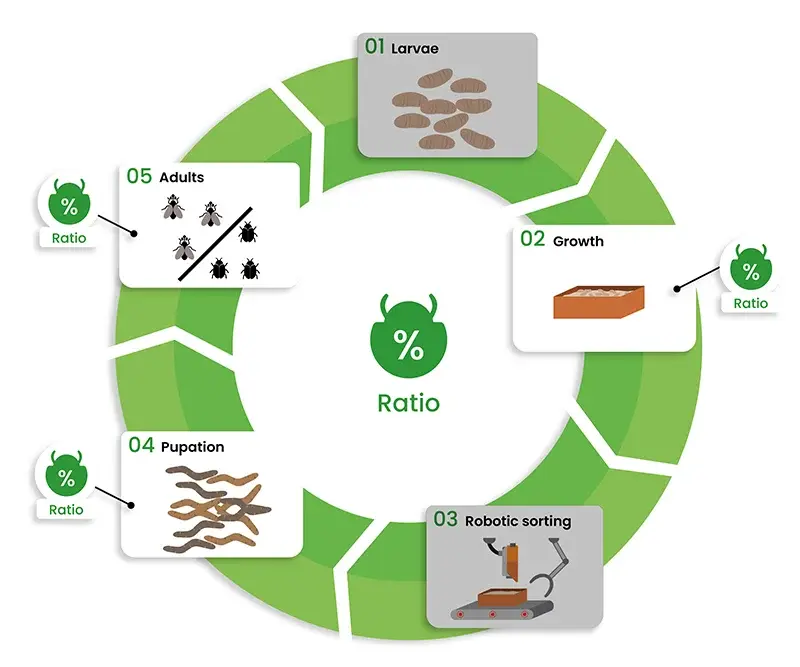

Measure your ratios automatically

Instantly estimate the proportions in your production batches with the DPX-Ratio software solution which allows you to measure different ratios.

Page in progress

Measure larvae activity

Upcoming

Offer under development

Cloud

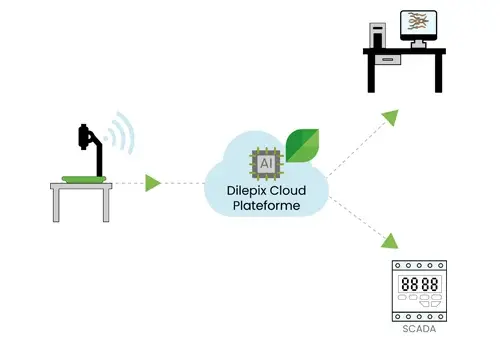

#5 A simple solution adapted to your stage of maturity

The Dilepix cloud-hosted solution analyzes images captured by a single camera in seconds and sends the results to a Dilepix interface or directly to your SCADA.

- Use of the Dilepix Webapp

- API to feed directly your SCADA

Embedded

#6 A solution that integrates into your production tools

Our solutions can also be embedded directly on your production lines to control robotic actions. We can work with an integrator to power your SCADA.

Learn more about our technology

#7 What can you expect as results on your business?

Consistent reliability even with a large number of analyses

Make the analysis data from your control stations more reliable.

Unlike a human operator for whom concentration will decrease as the day goes on, the solution proposed by Dilepix remains constant and can work 24/7.

Reproducible regardless of the number of checkpoints

Manage production and quality data feedback with a solution that can be reproduced over and over again.

Present on different stations of a plant or on different plants, the analysis points all work with the same precision and allow to analyze the performances at different scales.

A scalable solution

Adapt our solution to your industrial equipment.

Easily accessible from the Cloud, it can also be physically embedded on production lines to control robotic actions (work with your integrator).

Both in the cloud and embedded, the analysis results can be directly transmitted to your production control systems (SCADA).

#8 The benefits for you

- Our technology is robust and adapted to the technical constraints of buildings and agricultural factories

- It is extremely reliable and has very little margin for error

- It saves precious time in data analysis and counting

- It allows you to react at the right time

- It allows you to perform analyzes without interrupting your production chain

- It secures the monitoring of your production units

#9 Why should you work with Dilepix?

- Our technology based on artificial intelligence brings a very high level of accuracy.

- We are one of the few companies to develop our own neural networks.

- More robust and perfectly adapted to the harsh conditions of insect farms and factories, our algorithms, combined with camera vision, provide remarkable accuracy.

- Our solutions are developed in partnership with leading national technical institutes and/or with our customers' technical experts. We attach great importance to the scientific validation of our solutions.

- Our technology is designed for high precision operations, in real time and in industrial production conditions (heat, humidity, dust, light...).

#10 Frequently asked questions (FAQ)

- Do you already work with companies specialized in insect production?

Yes, our software has been developed with industrial insect producers.

- Do you have CIR and/or CII approval?

- On which insect species is your software effective?

👉 The next features of Prolarvae will concern the counting of 14 and 28 DOL BSF as well as the counting on sample up to 1000 larvae without frass.

For other species like Mealworm (Tenebrio molitor) our development roadmap includes a specific version.

👉 If you wish to benefit from these features before the mealworm version is available, please contact us

Control of insect production

Discover how our software will increase your production

- Improve the quality control,

- Reduce the production costs,

- Rationalize the production process

- Improve safety

- Automate your production line

Dilepix' blog

The 6 Levels of Autonomy in Agricultural Machinery

When people think of autonomous vehicles, they often picture self-driving cars navigating city streets....

Dilepix at Agritechnica 2023

Join us on our booth A20 in Hall 7 from November 11th to 18th, 2023 at the forefront of agricultural...

Meet Dilepix at LFDay 2023

Created in 2017, LFDay is the first event dedicated to agricultural and food innovation in France!

LOADIX autonomous robot: the collaboration between...

LOADIX, the autonomous, multi-tool, electric machine designed by ManuRob (M-extend Group) is a "farm valet"...

Newsletter subscription

Every month, receive a concentrate of artificial intelligence in your mailbox!

By subscribing to our free newsletter, you will benefit from :

- Our technical contents written by our teams

- Our advice for the use of AI in livestock farming

- Our educational tools to better understand what deep learning is

- Our latest news

- Our events

Dilepix and its logo are trademarks of Dilepix SA. All copyrights reserved © 2018 - 2024